Want to know more about us? We welcome your enquiry – please give us

a call. Contact us on the details below or email us your data and we’ll get

back to you to discuss your requirements

Quick links

Technical Support

About us

Contact us

Home

Insights/News

Our services

Quality

39a Millers Road

Warwick

Warwickshire

CV34 5AE

UK

01926-402261

2018-2023 Technical Support

Privacy policy

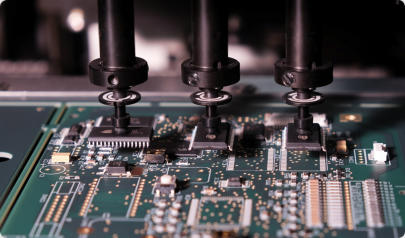

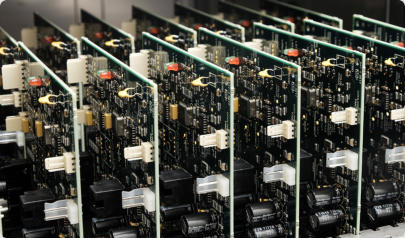

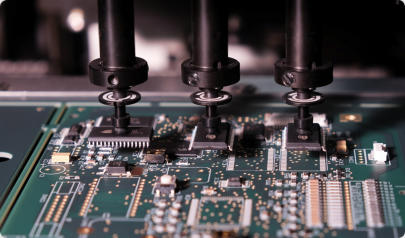

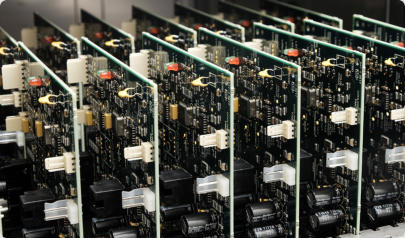

PCB Assembly

Purchasing & Kitting

AOI - Automated Optical Inspection

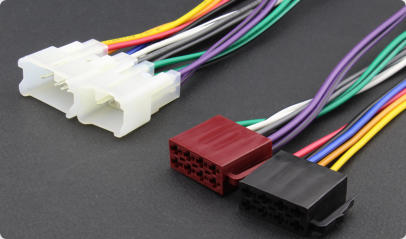

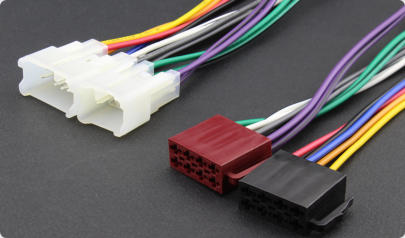

Cables & Sub- Assemblies

Programming & Testing

Cleaning

Other Services

We provide service to manufacturers across the UK, and are local to Leamington Spa, Coventry, Rugby, Daventry, Birmingham. and Stratford-on-Avon.

See our location here.

Want to know more about us? We welcome

your enquiry – please give us a call. Contact us

on the details below or email us your data and

we’ll get back to you to discuss your

requirements

Quick links

Technical Support

About us

Contact us

Home

Insights/News

Our services

Quality

39a Millers Road

Warwick

Warwickshire

CV34 5AE

UK

01926-402261

2018-2023 Technical Support | Privacy policy

PCB Assembly

Purchasing & Kitting

AOI

Automated Optical Inspection

Cables & Sub- Assemblies

Programming & Testing

Cleaning

Other Services

We provide service to manufacturers across the UK, and

are local to Leamington Spa, Coventry, Rugby, Daventry,

Birmingham. and Stratford-on-Avon.

See our location here.

Want to know more about us? We welcome your enquiry – please give us

a call. Contact us on the details below or email us your data and we’ll get

back to you to discuss your requirements

Quick links

Technical Support

About us

Contact us

Home

Insights/News

Our services

Quality

39a Millers Road

Warwick

Warwickshire

CV34 5AE

UK

01926-402261

2018-2023 Technical Support

Privacy policy

PCB Assembly

Purchasing & Kitting

AOI - Automated Optical Inspection

Cables & Sub- Assemblies

Programming & Testing

Cleaning

Other Services

We provide service to manufacturers across the UK, and are local to Leamington Spa, Coventry,

Rugby, Daventry, Birmingham. and Stratford-on-Avon.

See our location here.